Booth No. W4T17 of the 16th China International Foundry Expo in 2018

Release time:

2018-01-17

2. The following figure is the electric furnace charging car:

3. The following figure is the dust removal system:

4. The following figure is the automatic weighing system for alloy after furnace: it is used for automatic weighing and automatic input of alloy materials required for electric furnace smelting. All kinds of alloy materials are stored in high-position silo respectively, which are fed by electromagnetic vibration feeder, weighed by bottom-opening weighing hopper and transported by belt conveyor. The materials are distributed to the alloy storage hopper on the electric furnace charging truck by the lifting hopper and the moving hopper. Can automatically distribute a variety of alloy materials, high precision ingredients, ingredients data automatic record preservation.

5. The following figure shows the automatic weighing system of pre-furnace inoculant: it is used for automatic weighing and automatic input of pre-furnace inoculant. All kinds of inoculant are stored in the high-position silo respectively, which are fed by electromagnetic vibration feeder, weighed by bottom-open weighing hopper and transported by belt conveyor. Can automatically distribute a variety of inoculant, high precision ingredients, ingredients data automatic record preservation. The system can be interlocked with the molten iron truck, the truck reaches the inoculant receiving level, and the inoculant is automatically put into the molten iron truck.

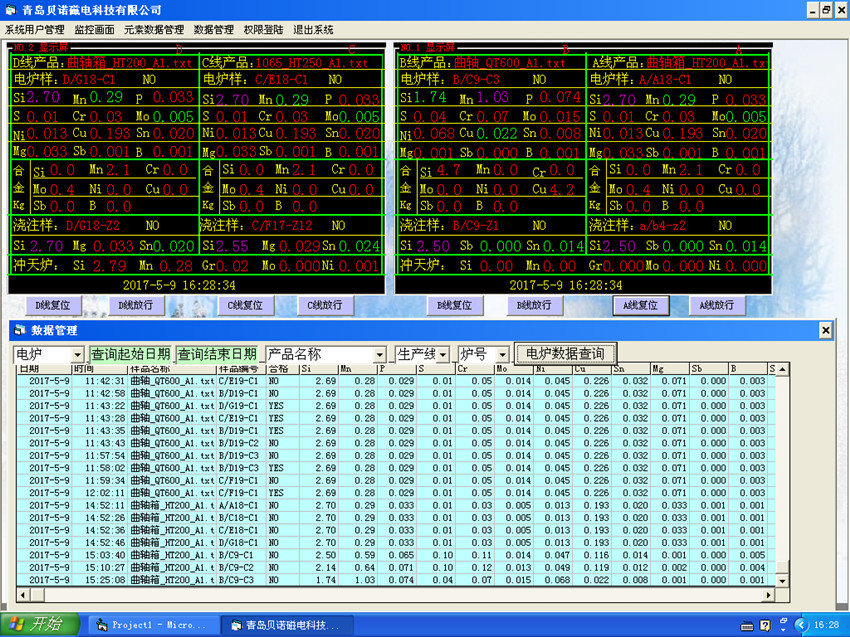

6. The following figure is a computer management system for smelting and batching: industrial-grade computers are used to carry out centralized and comprehensive monitoring and management of the electric furnace and batching and the smelting process. The system software can store and set the ingredient formula, record the ingredient data, and generate the ingredient data report. The system can be connected with thermal analyzer, spectrum analyzer, thermometer and other equipment to collect data of melting process, which is convenient for users to control and manage the melting process.

7. The following figure shows the large LED data display screen: the LED dot matrix large screen is used to display the electric furnace and ingredients data, spectral analysis data, thermal analysis data, etc., for the operator to monitor the smelting process.

8. The following figure shows the natural gas baking device: it is a special equipment for drying and baking new and heated ladles in the ironmaking process, and it can also quickly heat and heat up the ladles waiting for tapping. Adopt vertical structure, cover can be vertical lifting. Combustion air is supplied by a high-pressure fan until combustion is carried out by a burner installed in the center of the cover. The flame size of the baking bag can be adjusted manually, and the flame size can also be set to automatically adjust the temperature control and the baking curve can be set to automatically control the temperature and bake.

9. Polishing and dust removal telescopic room as shown below:

May 16-19, 2018, the 16th China International Foundry Expo, our company will bring its main products to participate in the exhibition, our booth number: W4T17, you are welcome to visit.

8. The following figure shows the natural gas baking device: it is a special equipment for drying and baking new and heated ladles in the ironmaking process, and it can also quickly heat and heat up the ladles waiting for iron. Adopt vertical structure, cover can be vertical lifting. Combustion air is supplied by a high-pressure fan until combustion is carried out by a burner installed in the center of the cover. The flame size of the baking bag can be adjusted manually, and the flame size can also be set to automatically adjust the temperature control and the baking curve can be set to automatically control the temperature and bake. 8. The following figure shows the natural gas baking device: it is a special equipment for drying and baking new and heated ladles in the ironmaking process, and it can also quickly heat and heat up the ladles waiting for iron. Adopt vertical structure, cover can be vertical lifting. Combustion air is supplied by a high-pressure fan until combustion is carried out by a burner installed in the center of the cover. The flame size of the baking bag can be adjusted manually, and the flame size can also be set to automatically adjust the temperature control and the baking curve can be set to automatically control the temperature and bake. 8. The following figure shows the natural gas baking device: it is a special equipment for drying and baking new and heated ladles in the ironmaking process, and it can also quickly heat and heat up the ladles waiting for iron. Adopt vertical structure, cover can be vertical lifting. Combustion air is supplied by a high-pressure fan until combustion is carried out by a burner installed in the center of the cover. The flame size of the baking bag can be adjusted manually, and the flame size can also be set to automatically adjust the temperature control and the baking curve can be set to automatically control the temperature and bake.

Latest news